Close search

Published :

/

Published :

/ Posted by : Retch

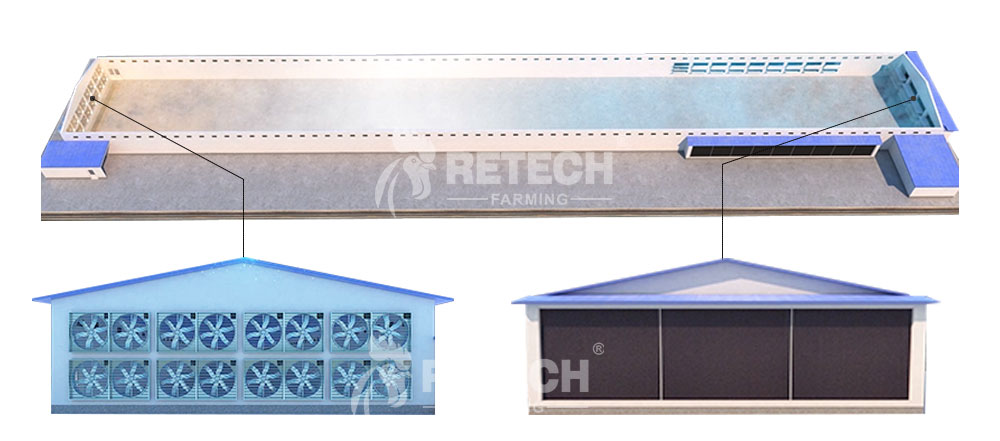

Posted by : RetchThe cooling systems are becoming increasingly popular in poultry houses today due to their ability to reduce the temperature while maintaining a consistent level of humidity. So how does this system work to affect the temperature and humidity inside the chicken house? The cooling pads are installed at the front of the chicken shed, which absorb and evaporate moisture, cooling the environment, then exhaust fans help to move air throughout the house. While it may be simple to understand how these systems work, they require a more complex understanding of the relationship between temperature and humidity and its effect on poultry.

The relationship between temperature and humidity is linear, meaning as temperature goes up humidity goes down, and vice versa. This strategy works well for most tropical areas in the world, where high temperatures can create an unbearable environment for poultry. Not only does this cooling system keep chickens comfortable by regulating temperatures but also maintains optimal levels of humidity which is vital for physiological functions like respiration and metabolism. Through proper understanding and operation of evaporative cooling systems though, poultry owners can ensure their birds remain safe from extreme weather conditions at all times.

The cooling systems use a combination of air-moving techniques, cooling pads, and large tunnel exhaust fans to orchestrate the most efficient cooling effect in poultry houses. The technical understanding behind how these systems operate requires knowledge of the relationship between temperature and humidity and the effect it has on chickens. The linear relationship between these two elements is simple; as temperature increases, humidity decreases, and vice versa.

The effectiveness of an evaporative cooling system is dependant on how much air is passed through it. In order to optimize its performance, a lot of airflow must travel through the house to ensure that the conditions are just right for the chickens inside. It starts with cool cell pads at one end which takes advantage t the hot weather’s water evaporation potential while the tunnel exhaust fans provide ventilation near the other end so that just enough cooler outside air can enter and take over with an evenly distributed temperature for optimal comfort for all birds inside.

Maintaining proper temperature and humidity levels is essential for poultry health, and evaporative cooling systems are an efficient way to achieve this. To ensure the system works at peak performance, it is important to keep each component in good working order. For example, the cooling pads should be kept clean from dust and debris to ensure maximum absorption of moisture, while the tunnel exhaust fans need to be calibrated to deliver the right amount of air flow. By understanding the nuances behind these systems and taking proper care of them, poultry owners can rest assured that their birds will remain comfortable no matter what the weather brings.

The wind-chill effect also plays a major role in cooling, especially during hot weather conditions. While pads are important to provide additional cooling, tunnel fans are the critical component of a successful cooling system since they create the necessary air velocity for a wind-chill effect to take place. The large volume of airflow produced by the fan serves as the main source of cooling for birds. This is because it provides more effective sensible heat loss than any other component in the broiler house.

It's evident that effective tunnel ventilation is essential for proper functioning within hot weather conditions. Airflow generated from tunnel fans must move rapidly in order to generate a high enough wind-chill effect which serves as primary means for cooling in these circumstances. Therefore, sufficient air velocity by way of effective pad placement and active tunnel fans is key when considering broiler houses during high temperatures. Pads used together with updated fan technology can provide an optimal operating range and keep birds comfortable throughout such rigorous climate changes.

Having an effective cooling system in place is only half the battle when it comes to maintaining proper temperatures inside a chicken house. It is also important to ensure that all other components of the poultry environment, such as ventilation and insulation, are up to par so that chickens can stay cool and healthy. Proper weather-proofing of a building helps minimize heat gain from direct sunlight while also restricting airflow through cracks and other openings. These preventative measures can go a long way in keeping birds comfortable, even during the hottest of days.

Evaporative cooling systems can be beneficial to the poultry industry, especially when used in combination with tunnel ventilation. This allows the production of healthy, profitable flocks even in extreme summer conditions. However, the high humidity that these systems create is a risk to the birds and must be counteracted by ensuring adequate air movement. Growers need to understand that wind speed and airflow are paramount for keeping their birds alive, so they must maximize airflow if they want to get the most out of an evaporative cooling system.

Retech has been exploring and studying the poultry industry for over 30 years, we’re very familiar with your local market, helped many chicken farmers to achieve great success by renovating their farms and upgrading their equipment, with more than 30 years of production experience, we can design and manufacture both chicken house and chicken cage based on your need and requirement, we can provide clients with automatic layer cage, broiler cage, and pullet cage, with best quality raw material, state of art of technology, competitive price, good service before/after the sale.

So if you looking for a Poultry chicken business opportunity, and if you want to start your own Poultry Chicken Business, pls feel free to give us a call, would be more than happy to help you!

Website: www.retechfarming.com

Facebook: @retechfarmingchickencage 100k Followers

Whatsapp: +8618561818859

Email: director@retechfarming.com